Wifi Bts Cell Phone Guy Mast Tower

China Factory Wifi Bts Cell Phone Guy Mast Tower

Guyed towers are known for their distinctive appearance, with their tall, slender structure supported by steel guy wires that give them a novel and striking look. This design feature is the tower’s most prominent characteristic, as it provides essential reinforcement and stability. As a common type of communication tower, the guyed tower is favored for its economic and practical advantages. Compared to other types of towers, it is lighter and more cost-effective, making it a popular choice for various applications. Additionally, its suitability for wide geographical areas further enhances its appeal, as it can efficiently serve communication needs across expansive regions.

Main Material:steel bar

Design Wind Speed:50M/S

Earthquake Intensity: 8°

Ice Coating:5mm-10mm(different in different regions)

Vertical Deviation:1/1000

Optimal Temperature:-45oC -+45oC

Preservative Treatment: hot-dipped galvanized

Work Life: more than 30years

Material Origin: Baosteel/Shousteel/Hansteel/Tangsteel

Wide Range of Applications

It can be installed in a load-bearing capacity of the roof, ground or slopes.

Item Specifics

|

Height

|

From 10M-100M or according to client’s requirement

|

|

Suit for

|

Electric Power Transmission and Distribution

|

|

Shape

|

According to client’s requirement

|

|

Material

|

Normally Q235B/A36,Yeild Strength≥235MPa

|

|

Q345B/A572,Yeild Strength≥345MPa

|

|

|

Tolerance of the dimension

|

According to client’s requirement

|

|

Surface treatment

|

Hot-dip-galvanized following ASTM123, or any other standard by client’s requirement

|

|

Joint of Poles

|

Slip joint, flanged connected

|

|

Standard

|

ISO9001:2008

|

|

Length of per section

|

Within 13M once forming

|

|

Welding Standard

|

AWS(American Welding Society)D 1.1

|

|

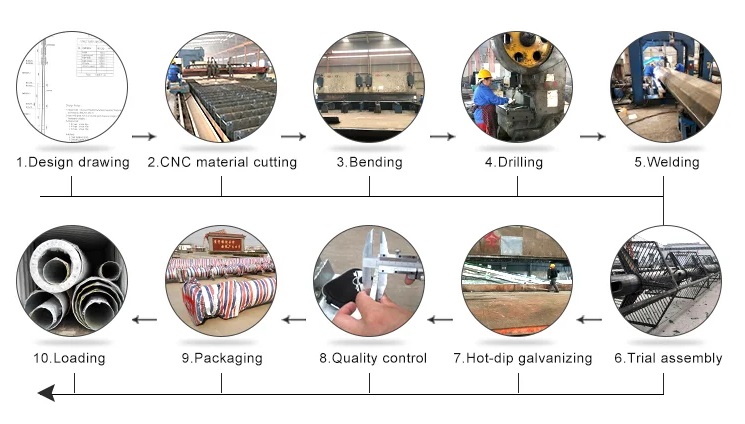

Production Process

|

Raw material test-cutting-bending-welding-dimension verify-flange welding-hole drilling-sample assemble-surface clean-galvanization-recalibration-packing

|

|

Packages

|

Packing with plastic paper or according to client’s requirement

|

|

Life Period

|

More than 30 years, according to installing environment

|

Product Process

Quality Commitment

In order to keep providing quality products, ensuring every pieces of products are perfect. We strictly inspect the process from the raw material purchasing to the final shipment and all steps are in charge by professional technicians. The production workers and QC engineers sign the Quality Assurance Letter with company. They promise they will be responsible to their job and products they manufacture should be quality.

we make a promise:

1. The products of our factory are strict accordance with customer’ requirements and national standard GB/T2694-2018《Technical Conditions for Manufacturing Transmission Line Towers》,DL/T646-1998《Technical Conditions for Manufacturing Transmission Line Steel Pipe Poles》and ISO9001 -2015 quality management system.

2. For the special requirements of the clients, the technical department of our factory will make drawings for customers. The customer should confirm the drawing and technical information are correct or not, then the production process shall be taken.

3. The quality of raw materials is significant for the towers. X.Y. Tower purchases raw materials from well-established companies and state-own companies. We also do physical and chemical experiment of the raw materials to make sure that the quality of raw materials must meet national standards or requirements of client. All the raw material of our company has product qualification certificate from steel- make company, while we make a detail record about where the raw material of product come from

CONTACT

Warmly Welcome To Contact US!

We provide the most professional one-stop steel tower service for Overseas export,specializing in power transmission line tower production, telecommunication tower production,

substation steel structure Works.

⦁ All kinds of telecom tower customized design can be provided

⦁ Own professional design team for overseas steel towers projects

To get professional quotations, please email to us or submit the following sheet, we will contact you in 24 hours and pls check your emailbox.