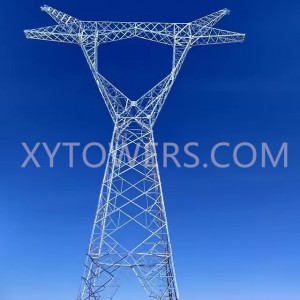

35KV Waist-type Angle Steel Electricity Transmission Line Tower

WHAT X.Y. TOWER DO

Look here, 15 years of Excellence, Rich overseas export experience

Our Team

⦁ Engineers team with average 20 years of work experience

⦁ One stop professional service is provided for overseas market

Our Story

⦁ a Chinese integrated electrical power company, mainly offers various electrical products to domestic and oversea energy utility companies and high-energy-usage industrial customers.

⦁ Specialize manufacturer in the field of 10kV-500kV transmission line tower/pole for electricity transmission and distribution, telecommunication tower/pole, substation structure, and steel fittings etc.

ITEM SPECIFICS

| Product Name | Electric power tower |

| Voltage Grade | 10~500KV |

| Raw Material | Q235B/Q355B/Q420B |

| Surface Treatment | Hot dip galvanized |

| Galvanized Thickness | average layer thickness 86um |

| Painting | customized |

| Bolts | 4.8;6.8;8.8 |

| Certificate | GB/T19001-2016/ISO 9001:2015 |

| Lifetime | More than 30 years |

| Keywords | Electrical Transmission Tower,Electric Power Tower,Power Transmission Towers,500kv Transmission Tower,Transmission Lattice Tower,China Transmission Tower Manufacture,China Electric Angle Steel Towers,China Lattice Towers,Lattice Transmission Tower |

| Manufacturing standard | GB/T2694-2018 |

| Galvanizing standard | ISO1461 |

| Raw material standards | GB/T700-2006, ISO630-1995, GB/T1591-2018;GB/T706-2016; |

| Fastener standard | GB/T5782-2000. ISO4014-1999 |

| Welding standard | AWS D1.1 |

| EU standard | CE : EN10025 |

| American Standard | ASTM A6-2014 |

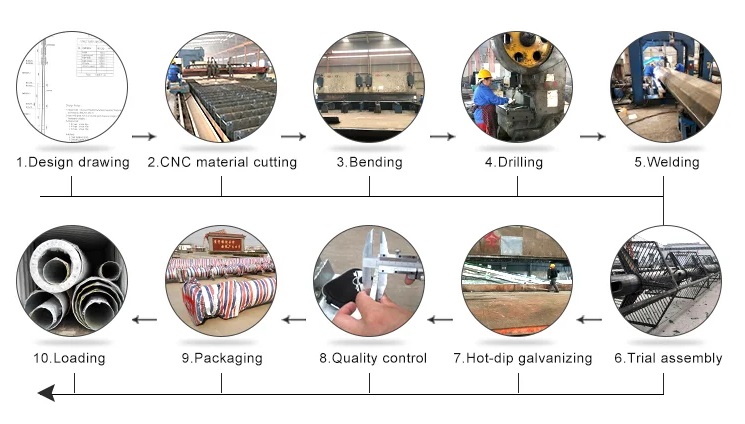

PRODUCT FLOW

GALVANZIED

After assembly & test, the next step will be carried out: hot dip galvanizing, which aims at beauty, rust prevention and prolonging the service life of the steel tower.

The company has own galvanizing plant, professional galvanizing team, experienced galvanizing teachers for guidance, and processing in strict accordance with ISO1461 galvanizing standard.

The following are our galvanizing parameters for reference:

|

Standard

|

Galvanized standard: ISO:1461-2002

|

|

Item

|

Thickness of zinc coating

|

|

Standard and requirement

|

≧86μm

|

|

Strength of adhesion

|

Corrosion by CuSo4

|

|

Zinc coat not be stripped and raised by hammering

|

4 times

|

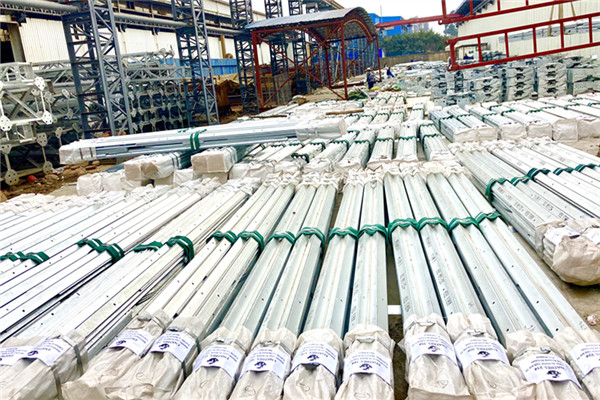

PACKAGE & SHIPMENT

Every piece of our products is coded according to the detail drawing. Every code will be put a steel seal on each piece. According to the code, clients will clearly know a single piece belong to which type and segments.

All the pieces are properly numbered and packaged through the drawing which could guarantee no single piece missing and easily to be installed.

ANY DETAILS PLEASE CONTACT US!!!