Steel Electric Pole

XYTOWER :

Steel Electric Pole

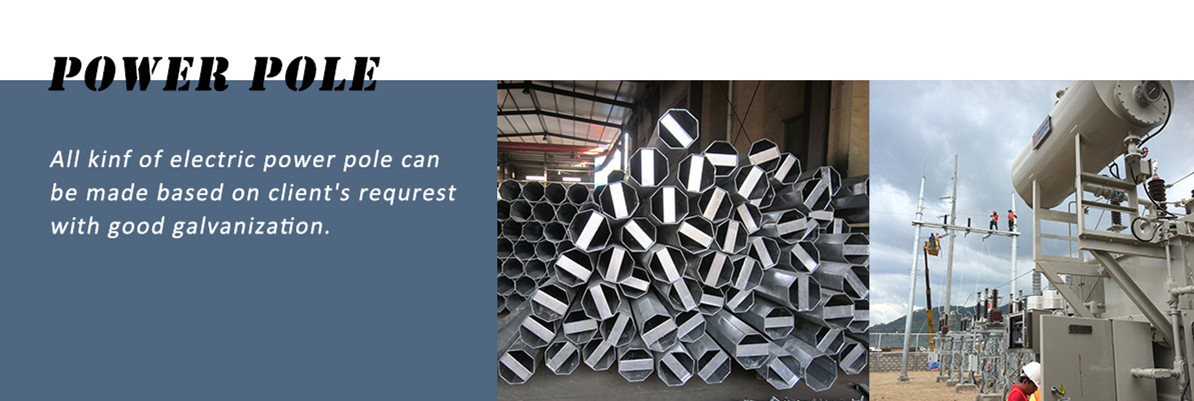

Steel Electric Pole is a crucial component of modern electrical infrastructure. As the name suggests, it is made of steel, which provides exceptional strength and durability. These poles are designed to support overhead power lines, transformers, and other electrical equipment.

One of the key advantages of Steel Electric Poles is their high resistance to adverse weather conditions such as strong winds, heavy rain, and lightning strikes. The robust steel construction ensures that these poles can withstand extreme environmental forces, reducing the risk of power outages and ensuring a reliable electricity supply.

Moreover, Steel Electric Poles are manufactured to meet industry safety standards. They are designed to minimize the risk of electric shock or accidents caused by proximity to high voltage power lines. Additionally, these poles are coated with anti-corrosion materials, ensuring a longer service life and minimizing maintenance requirements.

In terms of installation, Steel Electric Poles are relatively easy to assemble and install. They are available in various sizes and heights to meet the specific requirements of different electrical installations. Furthermore, these poles can be customized with brackets and attachments for accommodating street lights, CCTV cameras, and other infrastructure.

ISO9001 Hot Dip Galvanized Single Tube Tower

For power transmission towers in various situations, you are welcome to come for customized consultation, professional design team and one-stop service are provided!

We need customers to provide the following basic parameters: wind speed, voltage level, line return speed, conductor size and span

ITEM SPECIFICS

| Product name | Monopole tower For Transmission Line |

| Voltage grade | 33kV 35kV or other customized voltage |

| Raw Material | Q235B/Q355B/Q420B |

| Surface treatment | Hot dip galvanized |

| Galvanized thickness | Average layer thickness 86um |

| Painting | Customized |

| Bolts | 4.8;6.8;8.8 |

| Certificate | GB/T19001-2016/ISO 9001:2015 |

| Lifetime | More than 30 years |

MEETING STANDARDS

| Manufacturing standard | GB/T2694-2018 |

| Galvanizing standard | ISO1461 |

| Raw material standards | GB/T700-2006, ISO630-1995, GB/T1591-2018;GB/T706-2016; |

| Fastener standard | GB/T5782-2000. ISO4014-1999 |

| Welding standard | AWS D1.1 |

| EU standard | CE : EN10025 |

| American Standard | ASTM A6-2014 |

PACKING DETAILS

After the galvanizing process is over, we enter the packing stage. Each of our products is assigned a unique code based on detailed drawings. In addition, each product is stamped with a corresponding code. By referring to the code, our clients can easily determine the genre and market segment each piece belongs to.

To get professional quotations, please email to us or submit the following sheet, we will contact you in 24 hours! ^_^