4 Legs Steel Lattice Telecom Radio Antenna Tower

What We Do

X.Y. Towers is a leading company of high voltage transmission line in south west China.Established in 2008,as a manufacture and consulting company in field of Electrical and Communication Engineering,it has been providing EPC solutions to the growing demands of Transmission and Distribution(T&D)sector in the region.

Since 2008,X.Y towers has been involved in some of the largest and most complicated electrical construction projects in China.After 15 years of steady growth.we provide array of services within electrical construction industry which includes design and supply of transmission & distribution lines and electrical substation.

our core services and products comprise of:

Item Specifics

|

Product Name

|

Signal Tower |

|

Raw Material

|

Q235B/Q355B/Q420B

|

|

Surface Treatment

|

Hot dip galvanized

|

|

Galvanized Thickness

|

Average layer thickness 86um

|

|

Painting

|

Customized

|

|

Bolts

|

4.8;6.8;8.8

|

|

Certificate

|

GB/T19001-2016/ISO 9001:2015

|

|

Lifetime

|

More than 30 years

|

|

Manufacturing Standard

|

GB/T2694-2018

|

|

Galvanizing Standard

|

ISO1461

|

|

Raw Material Standards

|

GB/T700-2006, ISO630-1995, GB/T1591-2018;GB/T706-2016;

|

|

Fastener Standard

|

GB/T5782-2000. ISO4014-1999

|

|

Welding Standard

|

AWS D1.1

|

|

Design Wind Speed

|

30M/S (varies by regions)

|

|

Icing Depth

|

5mm-7mm: (varies by regions)

|

|

Aseismatic Intensity

|

8°

|

|

Preference Temperature

|

-35ºC~45ºC

|

|

Vertical Missing

|

<1/1000

|

|

Ground Resistance

|

≤4Ω

|

Telecom tower show

For telecom towers in various situations, you are welcome to come for customized consultation, professional design team and one-stop service are provided!

Structure Features

The angle steel tower adopts lattice structure, which has the following advantages

1. Wide at the top and sharp at the bottom, heavy at the top and light at the bottom, with strong wind resistance

2. Seismic resistance, integrity, good bearing capacity, high structural strength, good ductility, good integrity and high seismic performance

4. Easy assembly and installation

4. Large lifting machinery is not required.

5. Convenient for local adjustment

Standards

| Manufacturing standard | GB/T2694-2018 |

| Galvanizing standard | ISO1461 |

| Raw material standards | GB/T700-2006, ISO630-1995, GB/T1591-2018;GB/T706-2016; |

| Fastener standard | GB/T5782-2000. ISO4014-1999 |

| Welding standard | AWS D1.1 |

| EU standard | CE : EN10025 |

| American Standard | ASTM A6-2014 |

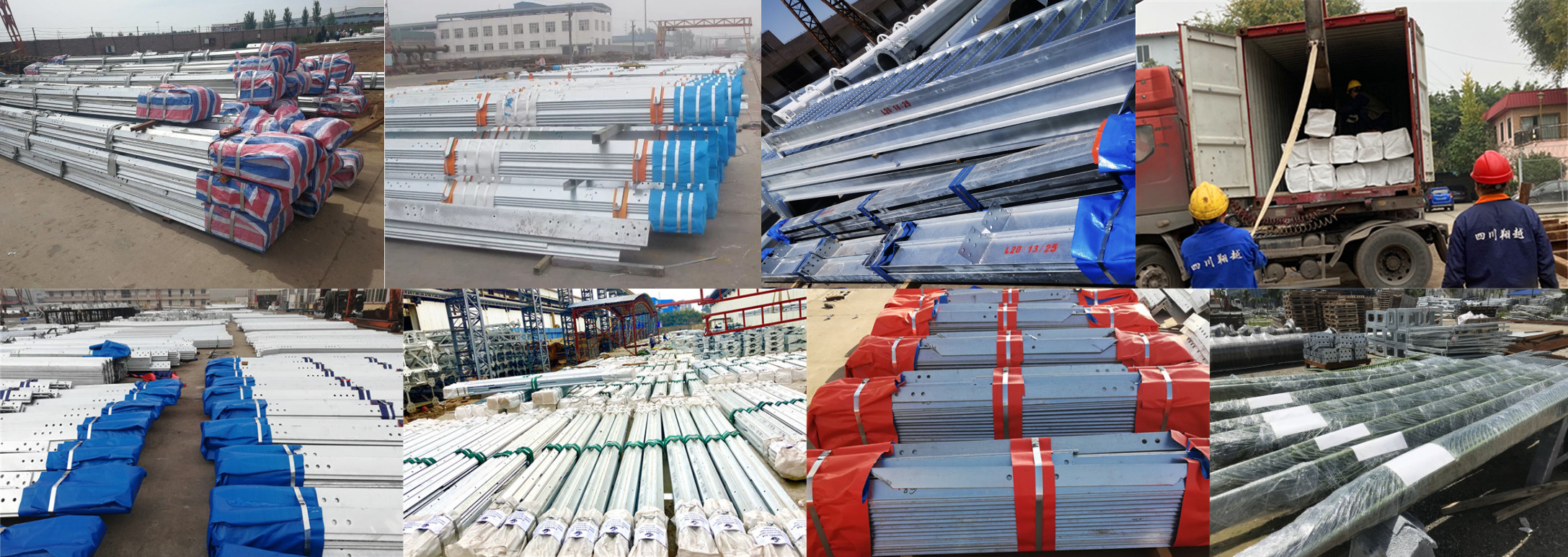

Package

Any questions, please feel free to consult!