50M Telecommunication Radio Broadcasting Angle Steel Tower

XYTOWER :

professional steel towers manufacturer and exporter

office

XYTOWER is an independent legal person qualification of enterprises, was founded in 2008,located strait Industrial Park, Wenjiang District, Chengdu, Sichuan Province,company set scientific research, production,management, sales as one, mainly offers various electrical products to domestic and oversea energy utility companies and high-energy-usage industrial customers,specializing in the field of transmission line tower/pole, telecommunication tower/pole,substation structure, and steel fittings etc.

workshop

The company has advanced production equipment,, we added a large number of new advanced equipmentwith an annual production capacity of 30000 tons of steel towers.

Unique company has perfect quality assurance system, stable and reliable product quality. products applicable to electrictransmission tower, railway, telecommunication, highways and other construction, the company’s products have been sold toworldwide countries, such as Nicaragua, Sudan, Myanmar, Mongolia, and other countries .

A microwave tower is also called a microwave communication tower. It is an iron tower supporting a parabolic antenna. It is mainly used for electronic systems for microwave transmission and reception. It is generally installed on a relatively high terrain. The microwave tower is generally a steel structure. Microwave communication towers generally hang directional antennas (plate-shaped) or omnidirectional antennas (rod-shaped) antennas, also known as communication towers.

Microwave communication towers are usually used in telegraph, telephone, production scheduling and broadcasting, television, flood control and other undertakings. It has the characteristics of low construction investment and high efficiency, so microwave communication is the main means of modern signal transmission.

|

Product Name

|

Broadcast Tower |

|

Raw Material

|

Q235B/Q355B/Q420B

|

|

Surface Treatment

|

Hot dip galvanized

|

|

Galvanized Thickness

|

Average layer thickness 86um

|

|

Painting

|

Customized

|

|

Bolts

|

4.8;6.8;8.8

|

|

Certificate

|

GB/T19001-2016/ISO 9001:2015

|

|

Lifetime

|

More than 30 years

|

|

Manufacturing Standard

|

GB/T2694-2018

|

|

Galvanizing Standard

|

ISO1461

|

|

Raw Material Standards

|

GB/T700-2006, ISO630-1995, GB/T1591-2018;GB/T706-2016;

|

|

Fastener Standard

|

GB/T5782-2000. ISO4014-1999

|

|

Welding Standard

|

AWS D1.1

|

|

Design Wind Speed

|

30M/S (varies by regions)

|

|

Icing Depth

|

5mm-7mm: (varies by regions)

|

|

Aseismatic Intensity

|

8°

|

|

Preference Temperature

|

-35ºC~45ºC

|

|

Vertical Missing

|

<1/1000

|

|

Key Word

|

Antenna Tower/Angle Tower/5g Tower/Internet Tower/Free Supporting Tower

|

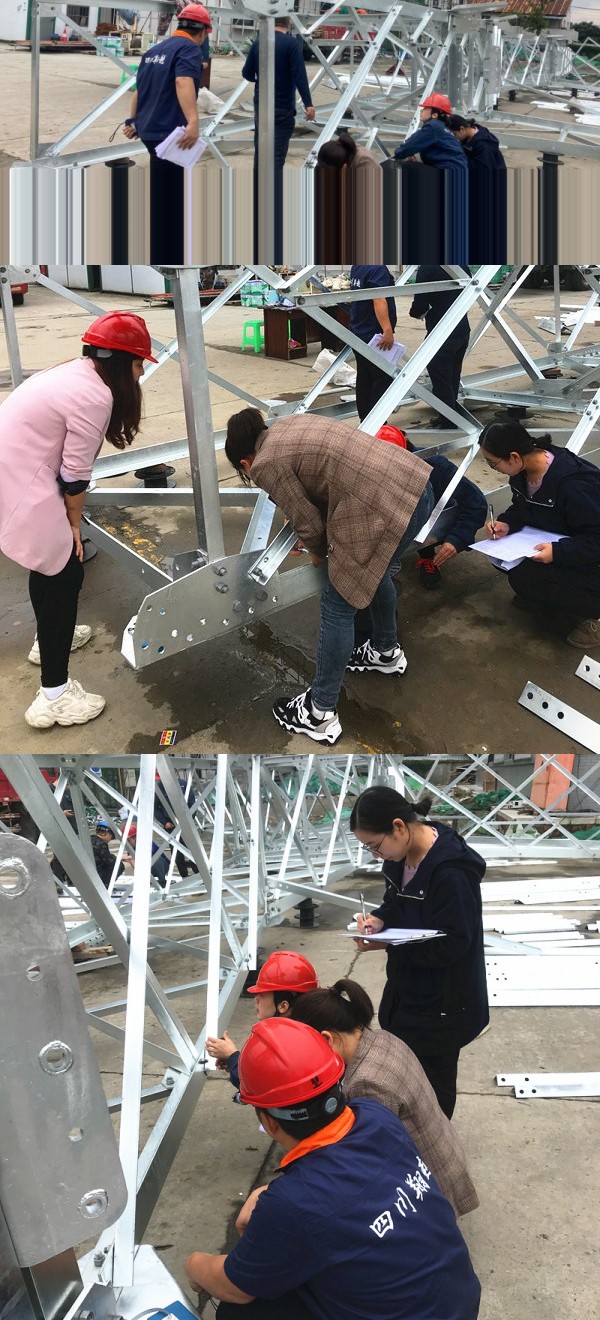

In order to ensure the product quality, we start from the procurement of raw materials. For the raw materials, angle steel and steel pipes required for product processing, our factory purchases the products of large factories with reliable quality throughout the country. Our factory also needs to inspect the quality of raw materials to ensure that the quality of raw materials must meet national standards and have the original factory certificate and inspection report.

After the production of the iron tower is completed, in order to ensure the quality of the iron tower, the quality inspector shall conduct assembly test on it, strictly control the quality, strictly control the inspection procedures and standards, and strictly inspect the machining dimension and machining accuracy according to the provisions of the quality manual, so as to ensure that the machining accuracy of parts meets the standard requirements.

Other Services:

1. The customer can entrust a third-party testing organization to test the tower.

2. Accommodation can be provided for customers who come to the factory to inspect the tower.

Myanmar electric tower assembly

East Timor telecom tower assembly

Nicaragua electric tower assembly

Assembled steel tower

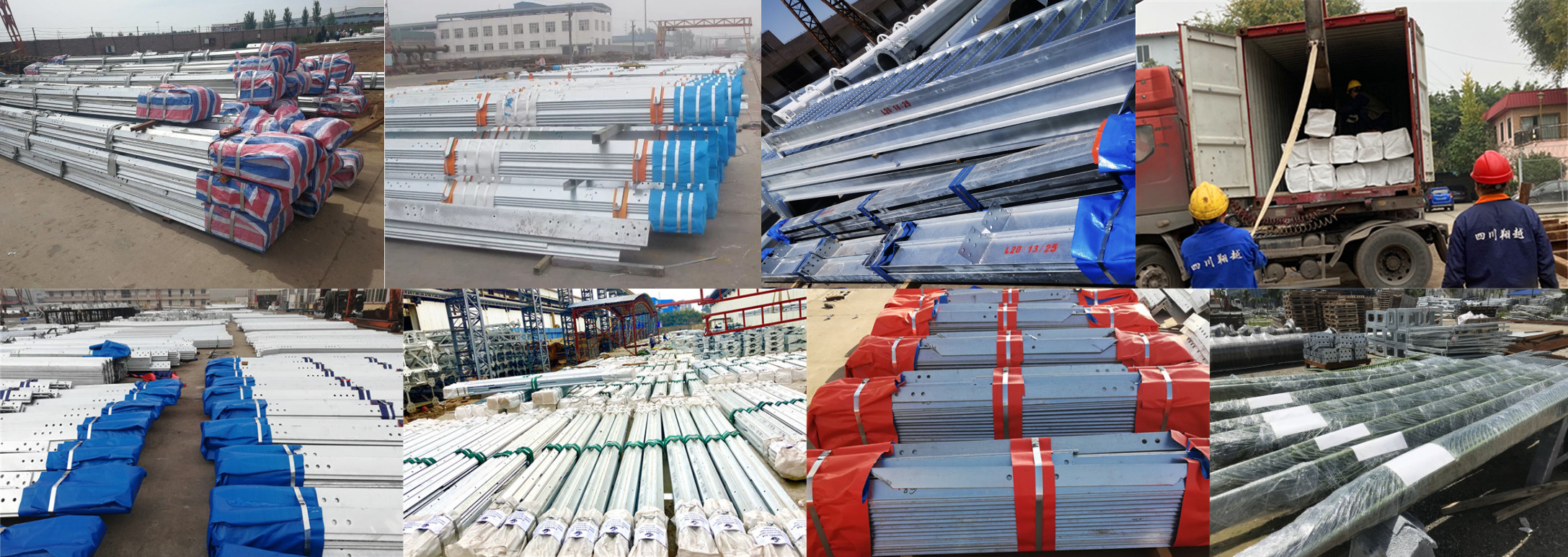

After Galvanization,we start to package,Every piece of our products is coded according to the detail drawing. Every code will be put a steel seal on each piece. According to the code, clients will clearly know a single piece belong to which type and segments.

All the pieces are properly numbered and packaged through the drawing which could guarantee no single piece missing and easily to be installed.

To get professional quotations, please email to us or submit the following sheet, we will contact you in 24 hours and pls check your emailbox.