China Supply Galvanised Steel Pipe Electric Transmission Line Tower

China Supply ------Galvanised Steel Pipe Electric Transmission Line Tower

The Electric Transmission Line Tower is an essential component in the field of electrical power transmission infrastructure. It serves a critical role in supporting and maintaining transmission lines that carry electricity from power plants to substations. This product is widely used across various industries, ensuring a reliable and efficient electricity distribution system.

The Transmission Line Tower is specifically designed to carry high-voltage power lines over long distances. Made primarily of galvanized steel pipes, which account for 3% of the overall product composition, this tower offers excellent resistance against corrosion. The galvanization process enhances the durability and longevity of the tower, even in harsh weather conditions.

Constructed to withstand high wind loads and other environmental factors, the Electric Transmission Line Tower is suitable for installation in diverse terrains. Its design prioritizes stability and structural integrity, minimizing the risk of collapse or damage during extreme weather events. This is crucial as it guarantees the uninterrupted flow of electricity and reduces the occurrence of power outages.

Manufactured with precision and strict quality control measures, the Electric Transmission Line Tower meets international standards and specifications. These rigorous standards ensure that the towers are reliable, safe, and equipped to tackle the challenges posed by electricity transmission.

The installation of these towers is a seamless process due to their modular design and prefabricated sections. This allows for quick and efficient assembly, reducing construction time and labor costs. The towers can be customized to meet specific project requirements, such as height, configuration, and capacity.

Moreover, the Electric Transmission Line Tower is not just a functional product; it also contributes to the overall aesthetic of the landscape. The towers are designed with visual appeal in mind, blending harmoniously with their surroundings. This careful attention to design ensures that they do not compromise the natural beauty and architectural integrity of the landscape.

XYTOWER :

professional steel towers manufacturer and exporter

XYTOWER is a company specialising in manufacturing various galvanized steel structures including Lattice Angle Tower, Steel Tube Tower, Substation Structure,telecommunication Tower,RoofTop Tower, and Power Transmission Bracket used for transmission lines up to 500kV.

XYTOWER focus on the production of hot dip galvanized steel towers for 15 years, have own factories and production lines, with an annual product of 30000 tons, sufficient supply capacity and rich export experience!

The company has advanced production equipment with an annual production capacity of 30000 tons of steel towers which have been sold toworldwide countries, such as Nicaragua, Sudan, Myanmar, Mongolia, Malaysia and other countries.

DESIGN SPECIFICATION:

|

Product

|

Power Electric Transmission Line Steel Tube Tower |

|

Height

|

From 10M-100M or according to client’s requirement |

| Suit for | Electric Power Transmission and Distribution |

| Shape | Polygonal or Conical |

|

Material

|

Normally Q235B/Q355B |

| Power Capacity | 10kV 11kV 33kV 35kV 66kV 110kV 132kV 220kV 330kV 500kV or other customized voltage |

| Tolerance of the dimension |

According to client’s requirement

|

|

Surface treatment

|

Hot-dip-galvanized following ASTM123, or any other standard |

| Joint of Poles | Slip joint, flanged connected |

| Standard | ISO9001:2015 |

| Length of per section | Within 13M once forming |

| Welding Standard | AWS(American Welding Society)D 1.1 |

| Production Process | Raw material test-cutting-bending-welding-dimension verify-flange welding-hole drilling-sample assemble-surface clean-galvanization or power coating /painting-recalibration-packages |

| Packages | Packing with plastic paper or according to client’s requirement |

| Life Period | More than 30 years, it is according to installing environment |

MATERIALS:

In order to ensure the product quality, we start from the procurement of raw materials. For the raw materials, angle steel and steel pipes required for product processing, our factory purchases the products of large factories with reliable quality throughout the country. Our factory also needs to inspect the quality of raw materials to ensure that the quality of raw materials must meet national standards and have the original factory certificate and inspection report.

ADVANTAGES:

1. An authorized supplier in Pakistan, Egypt, Tajikistan, Poland, Panama and other countries;

China Power Grid Certification supplier, you can safely choose and cooperate;

2. The factory has completed tens of thousands of project cases so far, so that we have a wealth of technical reserves;

3. Facilitating supports and low labor cost make the product price have great advantages in the world.

4. With a mature drawing and drawing team, you can rest assured of your choice.

5. Strict quality control system and abundant technical reserves have created world-class products.

6. We are not only manufacturers and suppliers, but also your partners and technical support.

ASSEMBLY & TEST OF STEEL TOWERS:

After the production of the iron tower is completed, in order to ensure the quality of the iron tower, the quality inspector shall conduct assembly test on it, strictly control the quality, strictly control the inspection procedures and standards, and strictly inspect the machining dimension and machining accuracy according to the provisions of the quality manual, so as to ensure that the machining accuracy of parts meets the standard requirements.

Other Services:

1. The customer can entrust a third-party testing organization to test the tower.

2. Accommodation can be provided for customers who come to the factory to inspect the tower.

HOT DIP GALVANIZATION:

After assembly & test, the next step will be carried out: hot dip galvanizing, which aims at beauty, rust prevention and prolonging the service life of the steel tower.

The company has own galvanizing plant, professional galvanizing team, experienced galvanizing teachers for guidance, and processing in strict accordance with ISO1461 galvanizing standard.

The following are our galvanizing parameters for reference:

|

Standard

|

Galvanized standard: ISO:1461

|

| Item |

Thickness of zinc coating

|

| Standard and requirement | ≧86μm |

| Strength of adhesion | Corrosion by CuSo4 |

| Zinc coat not be stripped and raised by hammering | 4 times |

PACKAGE:

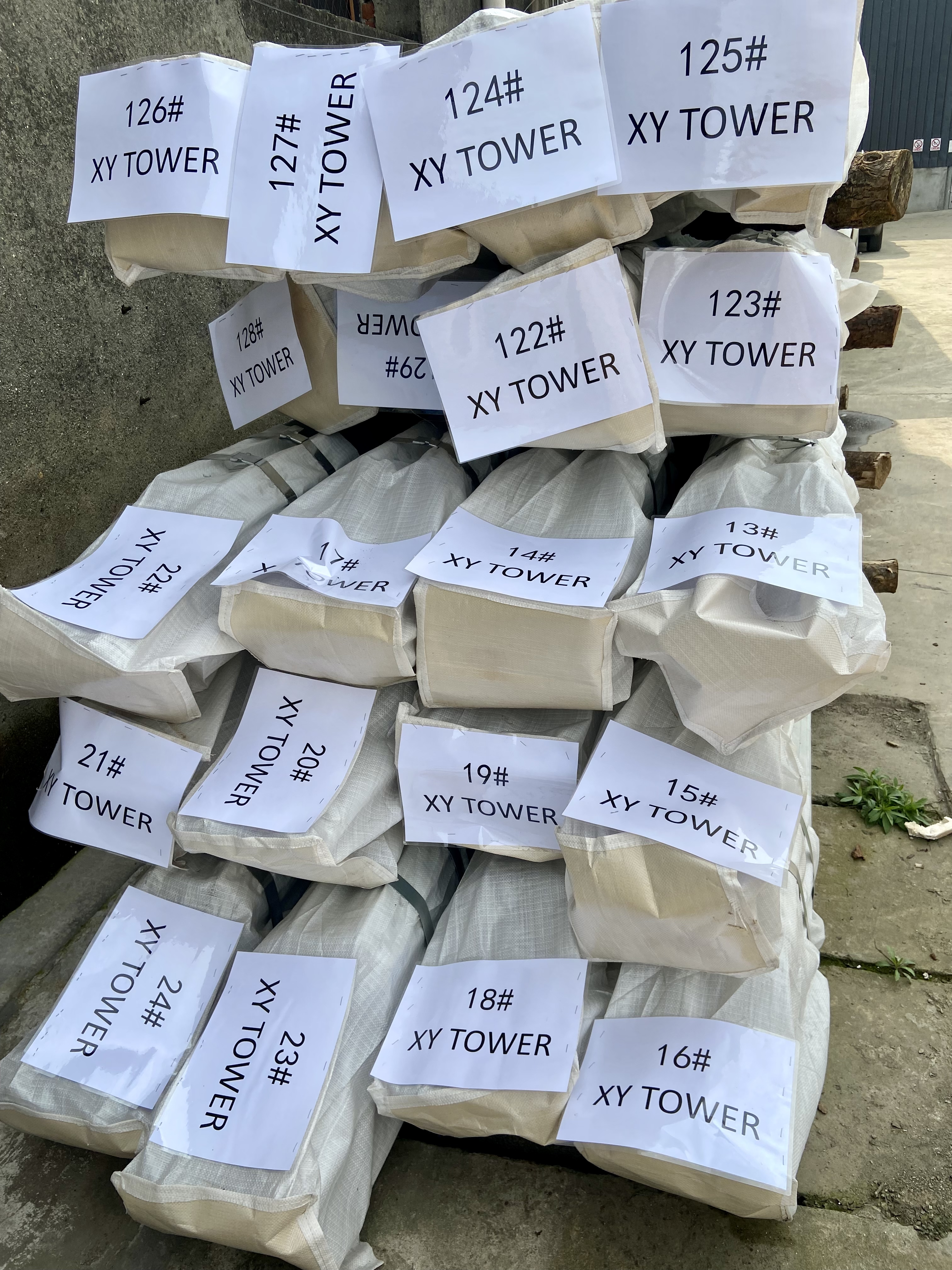

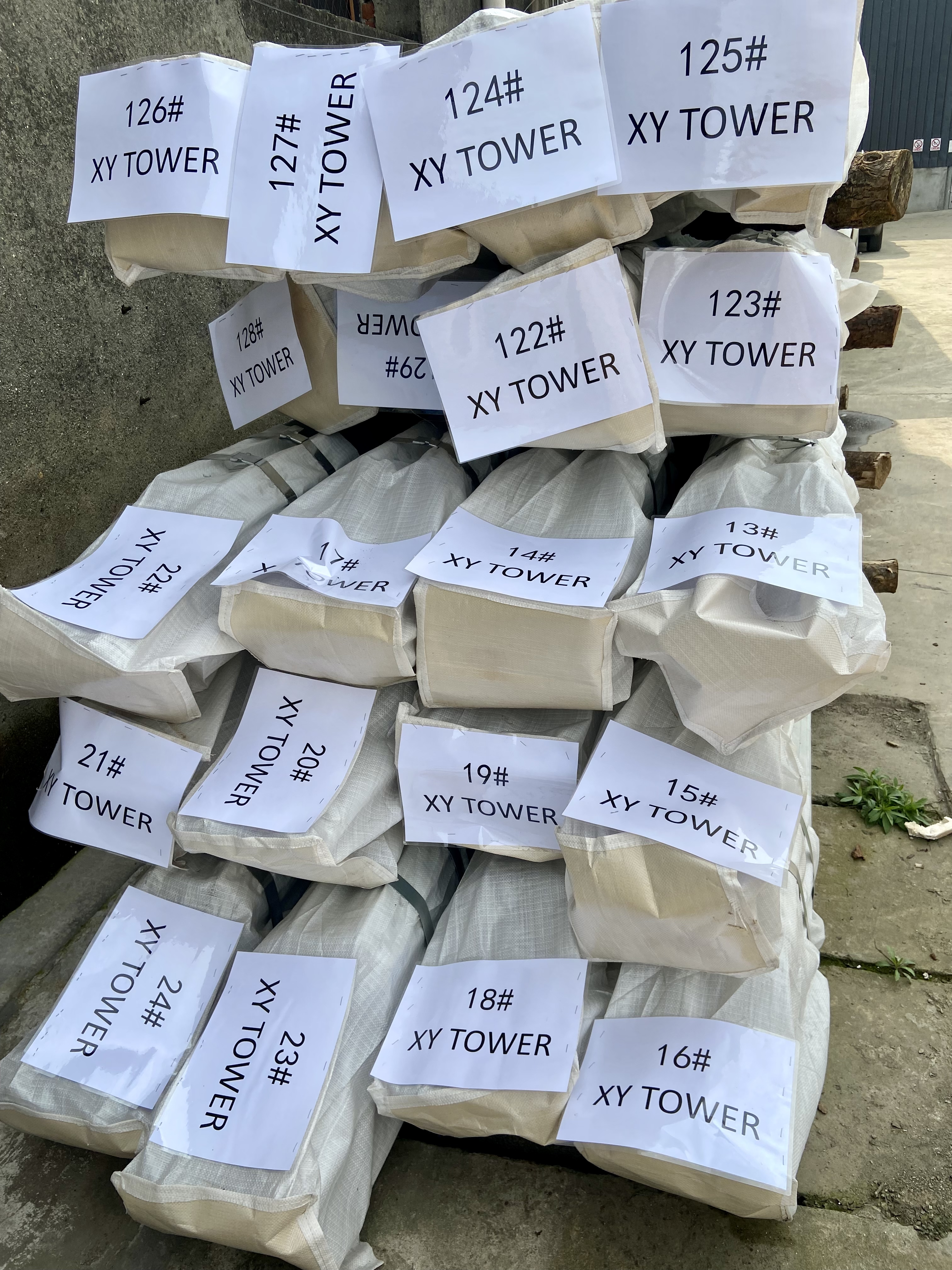

After Galvanization,we start to package,Every piece of our products is coded according to the detail drawing. Every code will be put a steel seal on each piece. According to the code, clients will clearly know a single piece belong to which type and segments.

All the pieces are properly numbered and packaged through the drawing which could guarantee no single piece missing and easily to be installed.

To get professional quotations, please email to us or submit the following sheet, we will contact you in 24 hours!