220KV/230KV Galvanized Octagonal Steel Electrical Power Transmission Line Tower

XYTOWER :

professional steel towers manufacturers and exporter

⦁ XYTOWER is a company specialising in manufacturing various galvanized steel structures and iron accessories,including Lattice Angle Tower, Steel Tube Tower, Substation Structure,telecommunication Tower,RoofTop Tower, and Power Transmission Bracket used for transmission lines up to 500kV,anchor bolts,hex head bolt and other screws.

⦁ XYTOWER focus on the production for 15 years, have own factories and production lines, with an annual product of 30000 tons, sufficient supply capacity and rich export experience!

⦁ WIth 15 years steel tower manufacturing experience,XYTOWER is a professional China supplier & exporter ,which has exported many different tower to foreign countries such as Nicaragua, Sudan, Myanmar, Mongolia,Malaysia,the Philippines and other countries.

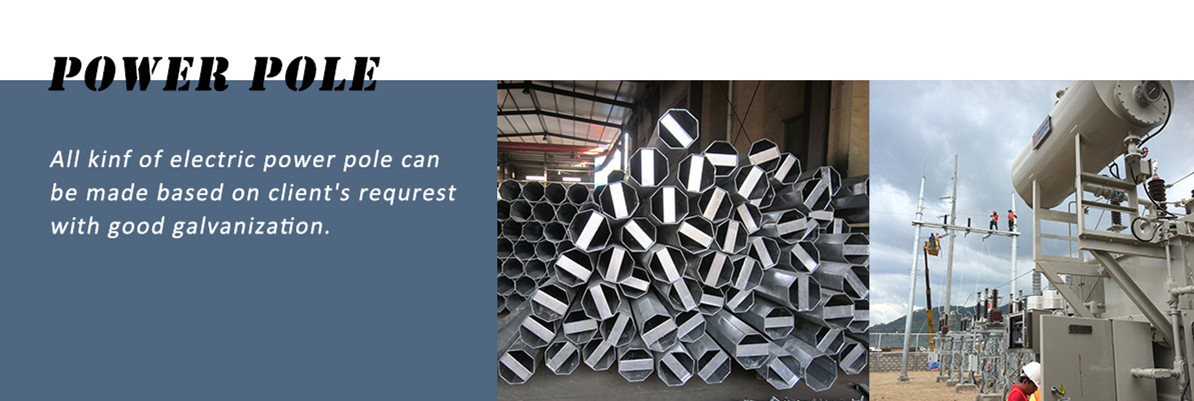

Monopole Transmission Tower

Electric poles are a general term referring to a variety of poles and towers that are used as the supporting structures for overhead power line conductors. Generally, the electric poles have the following characteristics:

1.A high level of mechanical strength, which allows it to bear the weight of conductors as well as other stresses like as wind.

2.Lightweight without impacting the material’s ability to withstand mechanical stress.

3.In terms of both initial and subsequent costs, the price is quite reasonable.

4.Longer life.

5.The conductors were designed to be easily accessible for maintenance purposes.

6.Wooden poles, concrete poles, steel poles, and rail poles are the many types of poles that are used for transporting overhead lines.

For power transmission towers in various situations, you are welcome to come for customized consultation, professional design team and one-stop service are provided!

ITEM SPECIFICS

| Height | From 10M-100M or according to client's requirement |

| Suit for | Electric Power Transmission and Distribution |

| Shape | Polygonal or Conical |

| Material | Normally Q235B/A36,Yeild Strength≥235MPa |

| Q355B/A572,Yeild Strength≥345MPa | |

| Hot Rolled coil from ASTM572, GR65,GR50,SS400 | |

| Power Capacity | 10kV to 500kV |

| Tolerance of the dimension | According to client's requirement |

| Surface treatment |

Hot-dip galvanized per ASTM123, or as required |

| Joint of Poles | Slip joint, flanged connected |

| Standard | ISO9001:2009 |

| Length of per section |

Within 12M once forming |

| Welding Standard |

AWS(American Welding Society)D 1.1 |

| Production Process |

Raw material test-cutting-bending-welding-dimension verify-flange welding-hole drilling-sample assemble-surface clean-galvanization or power coating /painting-recalibration-packages |

| Packages | Packing with plastic paper or according to client's requirement |

| Life Period | More than 30 years, it is according to installing environment |

| Keywords | Electric Power Tower,Transmission Line Pole,Transmission Monopole,Electricity Pole,Utility Pole,Electric Pole,Steel Pole,Electrical Power Pole,Transmission Pole |

MEETING STANDARDS

| Manufacturing standard | GB/T2694-2018 |

| Galvanizing standard | ISO1461 |

| Raw material standards | GB/T700-2006, ISO630-1995, GB/T1591-2018;GB/T706-2016; |

| Fastener standard | GB/T5782-2000. ISO4014-1999 |

| Welding standard | AWS D1.1 |

| EU standard | CE : EN10025 |

| American Standard | ASTM A6-2014 |

PACKING DETAILS

After the galvanizing process is over, we enter the packing stage. Each of our products is assigned a unique code based on detailed drawings. In addition, each product is stamped with a corresponding code. By referring to the code, our clients can easily determine the genre and market segment each piece belongs to.

To get professional quotations, please email to us or submit the following sheet, we will contact you in 24 hours! ^_^