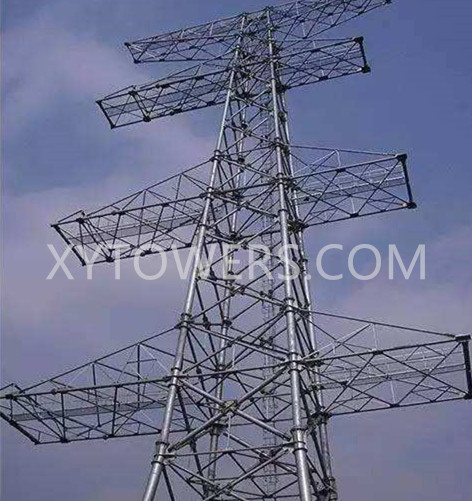

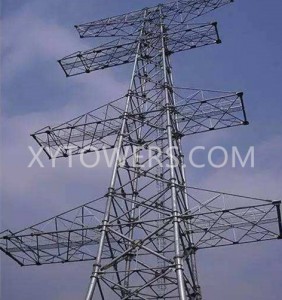

220kV Double Loop Transmission Tower

What We Do

⦁ a Chinese integrated electrical power company, mainly offers various electrical products to domestic and oversea energy utility companies and high-energy-usage industrial customers.

⦁ Specialize manufacturer in the field of transmission line tower/pole for electricity transmission and distribution, telecommunication tower/pole, substation structure, and steel fittings etc.

Our Vision

- ⦁ To be EFFECTIVE in performing our duties and providing services to internal and external customers.

Power Transmission Tower

A transmission tower or power tower (electricity pylon or electric pylon in the United Kingdom, Canada and parts of Europe) is a tall structure, usually a steel lattice tower, used to support an overhead power line.

They are used in high-voltage AC and DC systems, and come in a wide variety of shapes and sizes. Typical height ranges from 15 to 55 m (49 to 180 ft), though the tallest are the 370 m (1,214 ft) towers of a 2,700 m (8,858 ft) span of Zhoushan Island Overhead Powerline Tie. In addition to steel, other materials may be used, including concrete and wood.

Angle-steel tower, regular quadrangular truss structure communication tower, using Q345B high-quality steel as the main tower body material, rigid structure, small deformation; angle steel splicing connection, light-weight parts, tower can be manually transported and installed at low cost. Maximum 6 layers of platform can be equipped, each platform supports 6 antennas.

product information

| Material | Normally Q345B/A572, Minimum Yield Strength ≥ 345 N/mm² |

| Q235B/A36, Minimum Yield Strength ≥ 235 N/mm² | |

| As well as Hot rolled coil from ASTM A572 GR65, GR50, SS400, or any other standard by client required. | |

| Power Capacity | 200KV |

| Welding | Welding complies with AWS D1.1 standard. |

| CO2 welding or submerged arc auto methods | |

| No fissure, scar, overlap, layer or other defects | |

| Internal and external welding makes the pole more beautiful in shape | |

| If customers need any other requirements of welding, we also can make adjustment as your request | |

| Galvanization | Hot dip galvanization in accordance with Chinese standard GB/T 13912-2002 and American standard ASTM A123; or any other standard by client required. |

| Joint | Joint with insert mode, flange mode. |

| Painting | According to clients’ request |

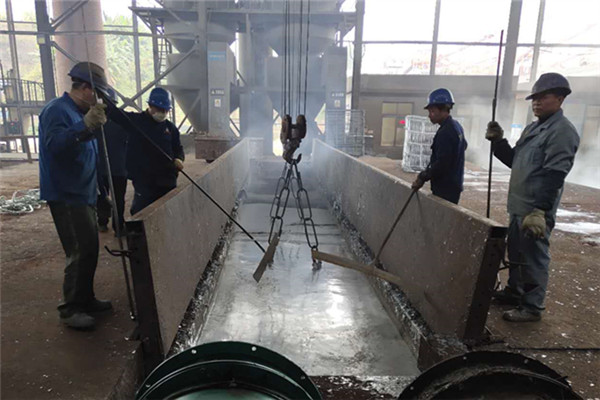

hot-dip galvanization

Galvanized standard: ISO:1461-2002

| Item | Thickness of zinc coating |

| Standard and requirement | ≧86μm |

| Strength of adhesion | Corrosion by CuSo4 |

| Zinc coat not be stripped and raised by hammering | 4 times |