330kV double loop terminal tower

Why X.Y. Tower

Infrastructure of X.Y. Tower:

The heart of any manufacturing facility is its infrastructure. X.Y. Tower has an installed capacity to manufacture 30,000 tons of towers per year.

X.Y. Tower is ready to meet the world's most stringent quality standards.

Well-engineered layouts, mechanized production equipment and large storage facilities for steel give X.Y. Tower quality products as per the stern requirements of customers.

The fabrication plant at Chengdu has been built on a plot measuring 35,000 sq. meter. It combines highly skilled manpower with modern manufacturing infrastructure to ensure products of the highest quality.

Built on another 7000 sq. meter of land for the galvanizing plant.

It incorporates the latest technology for hot dip galvanizing of a variety of structures.

Tower description

transmission tower is a tall structure, usually a steel lattice tower, use to support an overhead power line. We render these products with the help of

diligent workforce having vast experience in this field. We go through detailed line survey, route maps, spotting of towers, chart structure and technique document while providing these products.

Our product covers the 11kV to 500kV while include different tower type for example suspension tower, strain tower, angle tower, end tower etc.

Additionally, we still have a vast designed tower type and design service to be offered while if clients have no drawings.

| Product name | Transmission line tower |

| Brand | X.Y. Towers |

| Voltage grade | 220/330kV |

| Nominal height | 18-48m |

| Numbers of bundle conductor | 1-6 |

| Wind speed | 120km/h |

| Lifetime | More than 30 years |

| Production standard | GB/T2694-2018 or customer required |

| Raw Material | Q255B/Q355B/Q420B/Q460B |

| Raw Material standard | GB/T700-2006,ISO630-1995;GB/T1591-2018;GB/T706-2016 or Customer Required |

| Thickness | angel steel L40*40*3-L250*250*25; Plate 5mm-80mm |

| Production Process | Raw material test → Cutting →Molding or bending →Verification of dimensions →Flange/Parts welding →Calibration → Hot Galvanized →Recalibration →Packages→ shipment |

| Welding standard | AWS D1.1 |

| Surface treatment | Hot dip galvanized |

| Galvanized standard | ISO1461 ASTM A123 |

| Color | Customized |

| Fastener | GB/T5782-2000; ISO4014-1999 or Customer Required |

| Bolt performance rating | 4.8;6.8;8.8 |

| Spare Parts | 5% bolts will be delivered |

| Certificate | ISO9001:2015 |

| Capacity | 30,000 tons/ year |

| Time to Shanghai Port | 5-7 days |

| Delivery Time | Usually within 20 days depends on demand quantity |

| size and weight tolerance | 1% |

| minimum order quantity | 1 set |

Value-added Service

1、Customer reception service. We are very glad that our clients pay a visit to X. Y. Tower. We would like to provide 2-3 persons three days accommodation and other necessary help to our customers for free.

2、Trial assembly tower service. As long as clients require the trial assembly tower service, whatever clients come to factory or not, we will do trial assembly tower and take a video for future reference.

3、Daily update service:Once the contract is signed, an service team which include the person from production、QC、marketing department will be built. This dedicated team will give daily report via group chat of WhatsApp or WeChat and answer any question from clients in time, so the clients can keep tracking the production status.

4、5% more bolts & nuts will be provide for free to ensure installation.

5、Except to products, X.Y. Tower will provide the following certificates and reports

.Raw Material Report from steel mill

.X.Y. Tower Raw Material Reinspection report

.Tower parts inspection records from QC team

.X.Y. Tower Qualified products allow ex-factory certificate

.X.Y. Tower Qualified Galvanized certificate

. Certificate of Origin

TESTS

X.Y. Tower has a very strict test protocol to ensure all products we fabricate is quality. The following process is applied in our production flow.

Sections and Plates

1. Chemical composition (Ladle Analysis)

2. Tensile Tests

3. Bend Tests

Nuts and Bolts

1. Proof Load test

2. Ultimate Tensile Strength test

3. Ultimate tensile strength test under eccentric load

4. Cold bend test

5. Hardness test

6. Galvanizing test

All the test data are recorded and will be reported to the management. If any flaws are found, the product will be repaired or scraped directly.

Hot-dip galvanizing

Quality of Hot-dip galvanizing is one of our strength, Our CEO Mr. Lee is an expert in this field with reputation in Western-China. Our team has vast experience in HDG process and especially good at handling the tower in high corrosion areas.

Galvanized standard: ISO:1461-2002.

| Item |

Thickness of zinc coating |

Strength of adhesion |

Corrosion by CuSo4 |

| Standard and requirement |

≧86μm |

Zinc coat not be stripped and raised by hammering |

4 times |

Free prototype tower assembly service

prototype tower assembly is a very traditional but effective way to inspect whether the detail drawing is correct.

In some cases, clients still want to do prototype tower assembly to ensure the detail drawing and fabrication is OK. Hence, we still provide prototype tower assembly service for free to customers.

In prototype tower assembly service, X.Y. Tower makes commitment:

• For each member, the length, position of holes and interface with other members will be checked accurately for proper fitness;

• Quantity of each member and bolts will be carefully checked from the bill of materials when assembling the prototype;

• Drawings and bill of materials, sizes of bolts, fillers etc. will be revised if any mistake is found.

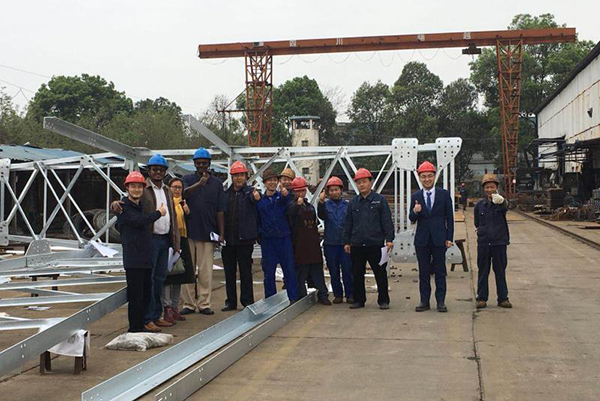

Customer visit service

We are so glad that our clients to visit our factory and inspect the product. It is a great chance for both sides to know each other better and strengthen cooperation.For our clients, we will receive you at Airport and provide 2-3 days accommodation.

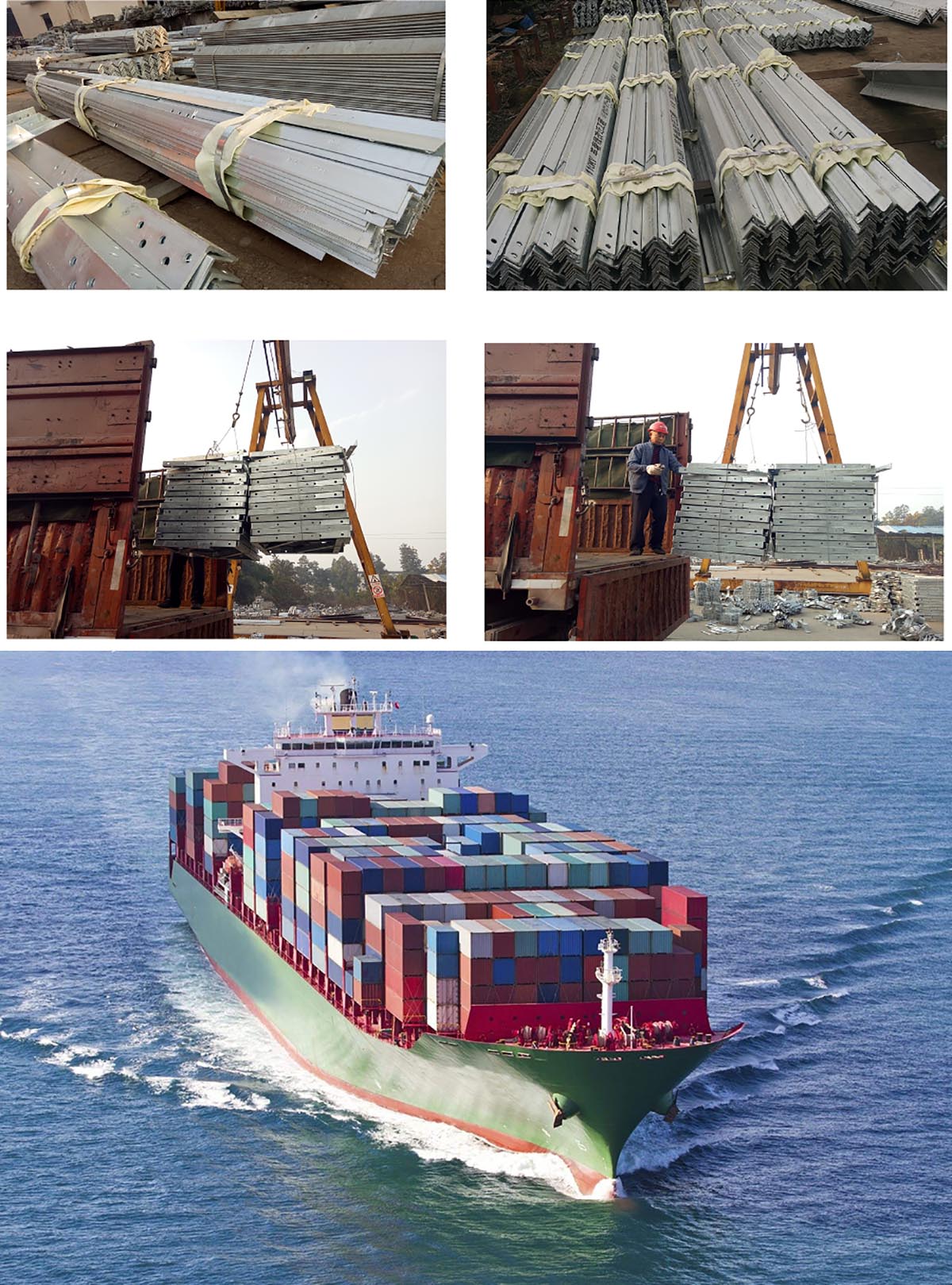

Package and shipment

Every piece of our products is coded according to the detail drawing. Every code will be put a steel seal on each piece. According to the code, clients will clearly know a single piece belong to which type and segments.

All the pieces are properly numbered and packaged through the drawing which could guarantee no single piece missing and easily to be installed.

Shipment

Normally, the product will ready in 20 working days after deposit. Then the product will take 5-7 working days to arrive at Shanghai Port.

For some countries or regions, like Central Asia, Myanmar, Vietnam etc., China-Europe freight train and carriage by land may be two better options of transportation.