132kV Single Circuit Angle Steel Tower

XYTOWER :

professional steel towers manufacturer and exporter

XYTOWER is a company specialising in manufacturing various galvanized steel structures including Lattice Angle Tower, Steel Tube Tower, Substation Structure, telecommunication Tower,RoofTop Tower, and Power Transmission Bracket used for transmission lines up to 500kV.

XYTOWER focus on the production of hot dip galvanized steel towers for 15 years, have own factories and production lines, with an annual product of 30000 tons, sufficient supply capacity and rich export experience!

The 10kV-500kV angle lattice steel tower designed and processed by the company have passed the type test (tower structure load test) at one time. Our goal is to strive to provide customers with satisfactory products and services.

Item Specifics

| Product name | 132KV Transmission line tower |

| Voltage grade | 110/132kV |

| Raw material | Q235B/Q355B/Q420B |

| Surface treatment | Hot dip galvanized |

| Galvanized thickness | average layer thickness 86um |

| Painting | customized |

| Bolts | 4.8;6.8;8.8 |

| Certificate | GB/T19001-2016/ISO 9001:2015 |

| Lifetime | More than 30 years |

Standards

| Manufacturing standard | GB/T2694-2018 |

| Galvanizing standard | ISO1461 |

| Raw material standards | GB/T700-2006, ISO630-1995, GB/T1591-2018;GB/T706-2016; |

| Fastener standard | GB/T5782-2000. ISO4014-1999 |

| Welding standard | AWS D1.1 |

| EU standard | CE : EN10025 |

| American Standard | ASTM A6-2014 |

Single circuit vs Double circuit

Quality Commitment

In order to keep providing quality products, ensuring every pieces of products are perfect. We strictly inspect the process from the raw material purchasing to the final shipment and all steps are in charge by professional technicians. The production workers and QC engineers sign the Quality Assurance Letter with company. They promise they will be responsible to their job and products they manufacture should be quality.

we make a promise:

1. The products of our factory are strict accordance with customer’ requirements and national standard GB/T2694-2018《Technical Conditions for Manufacturing Transmission Line Towers》,DL/T646-1998《Technical Conditions for Manufacturing Transmission Line Steel Pipe Poles》and ISO9001 -2015 quality management system.

2. For the special requirements of the clients, the technical department of our factory will make drawings for customers. The customer should confirm the drawing and technical information are correct or not, then the production process shall be taken.

3. The quality of raw materials is significant for the towers. X.Y. Tower purchases raw materials from well-established companies and state-own companies. We also do physical and chemical experiment of the raw materials to make sure that the quality of raw materials must meet national standards or requirements of client. All the raw material of our company has product qualification certificate from steel- make company, while we make a detail record about where the raw material of product come from

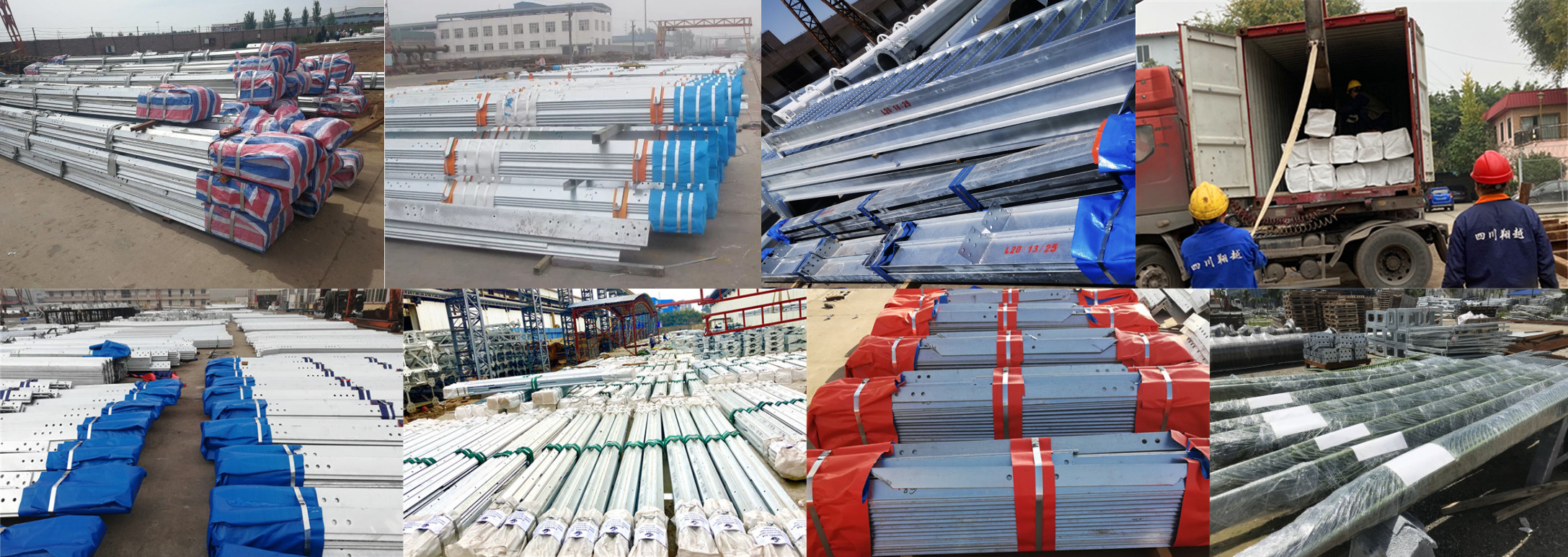

Package

After Galvanization,we start to package,Every piece of our products is coded according to the detail drawing. Every code will be put a steel seal on each piece. According to the code, clients will clearly know a single piece belong to which type and segments.

All the pieces are properly numbered and packaged through the drawing which could guarantee no single piece missing and easily to be installed.