132kV Double Circuit Straight Tower

Products Available at XY Towers

Product Introduction

Transmission line angle steel lattice tower is called angle tower for short, it‘s for electricity transmission and distribution,and by their shapes they are generally divided into five types: glass type, cathead type, fonts on type , dry fonts type and bucket type. By the uses, they can be divided into: tension tower, straight line tower, angle tower, transposition tower (to replace the position of wire phase), terminal tower and crossing tower, etc.

Features

1. Various towers are all lattice structure. Bars are composed of single equilateral angle steel or combination of angle steel.

2. The materials are generally Q235(A3F), Q345(16Mn) and Q420 The connection between the bars are crude bolts.

3. Hot dip galvanized anti-corrosion. Very convenient for transportation and construction erection.

4. To the towers, which vertical distance from horizontal ground to first-floor crossarm hang point is below 60 meters, we set foot nails on one of main legs to facilitate the construction workers to climb onto the tower for operation.

Item Specifics

| Height | 10kV-500kV, height–according to the parameters offered by customer |

| Wind pressure | 0~1kN/m2 (Chinese standard, other country’s standard may change based on it) |

| Wind speed | 0~180km/h (American standard 3s gust) |

| Foundation type | Independent foundation/Raft foundation/Pile foundation |

| Environment condition | Soft ground/Mountain groud |

| Type | Three-legged/Four-legged |

| Quality system | GB/T19001-2016/ISO 9001:2015 |

| Design standard | Chinese relative regulation/American standard G/American standard F |

| Material | Q235/Q345/Q390/Q420/Q460/GR65 |

| Galvanized | Hot dip galvanization (86μm/65μm) |

| Connection structure | Bolt |

| Lifetime | 30years,according to installing environment |

Hot Dip Galvanization

| Item | Thickness of zinc coating |

| Standard and requirement | ≧86μm |

| Strength of adhesion | Corrosion by CuSo4 |

| Zinc coat not be stripped and raised by hammering | 4 times |

Our CEO Mr. Lee is an expert in this field with reputation in Western-China. Our team has vast experience in HDG process and especially good at handling the tower in high corrosion areas. Galvanized standard: ISO:1461-2002.

Quality Commitment

In order to keep providing quality products, ensuring every pieces of products are perfect. We strictly inspect the process from the raw material purchasing to the final shipment and all steps are in charge by professional technicians. The production workers and QC engineers sign the Quality Assurance Letter with company. They promise they will be responsible to their job and products they manufacture should be quality.

we make a promise:

1. The products of our factory are strict accordance with customer’ requirements and national standard GB/T2694-2018《Technical Conditions for Manufacturing Transmission Line Towers》,DL/T646-1998《Technical Conditions for Manufacturing Transmission Line Steel Pipe Poles》and ISO9001 -2015 quality management system.

2. For the special requirements of the clients, the technical department of our factory will make drawings for customers. The customer should confirm the drawing and technical information are correct or not, then the production process shall be taken.

3. The quality of raw materials is significant for the towers. X.Y. Tower purchases raw materials from well-established companies and state-own companies. We also do physical and chemical experiment of the raw materials to make sure that the quality of raw materials must meet national standards or requirements of client. All the raw material of our company has product qualification certificate from steel- make company, while we make a detail record about where the raw material of product come from

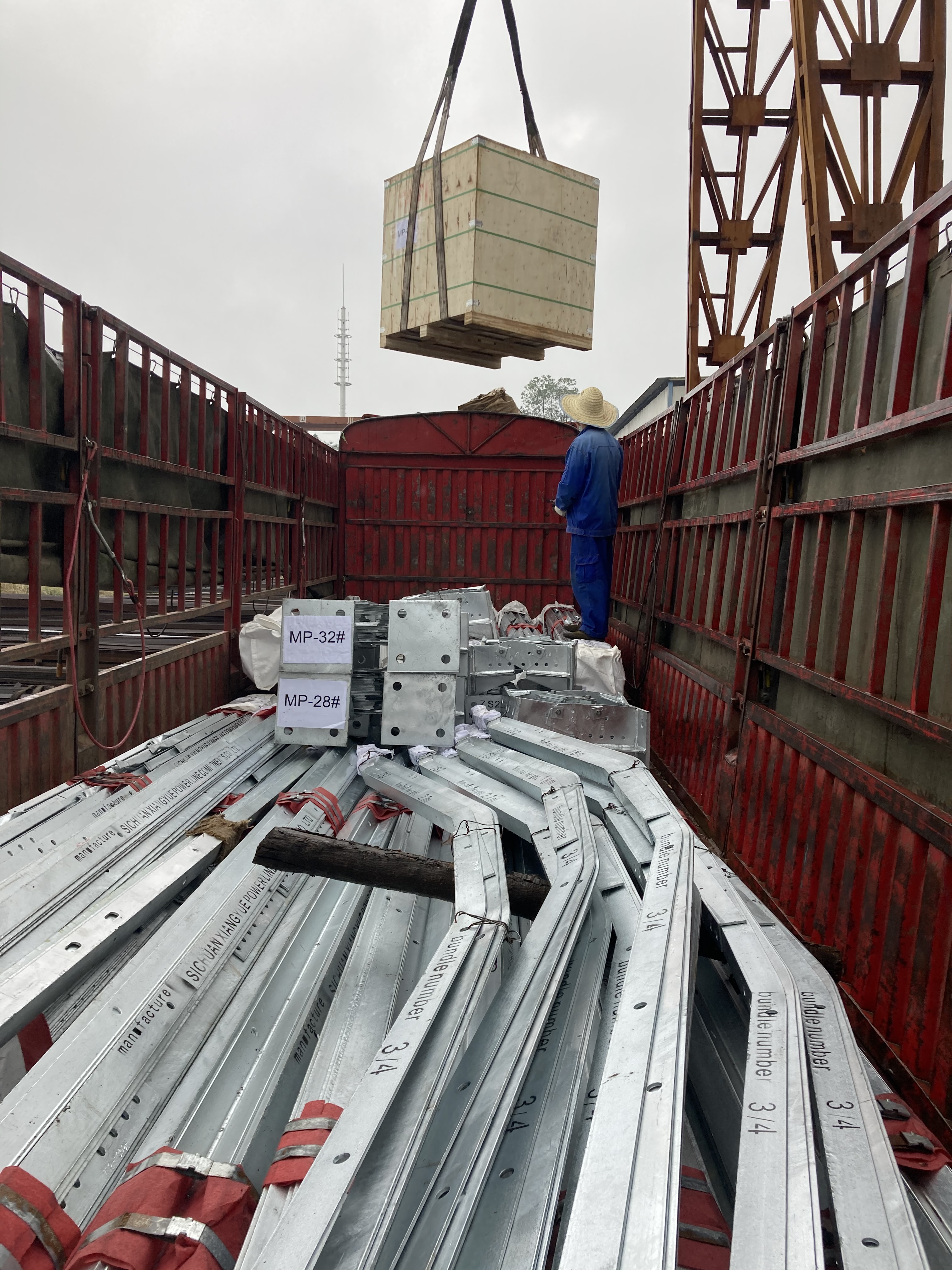

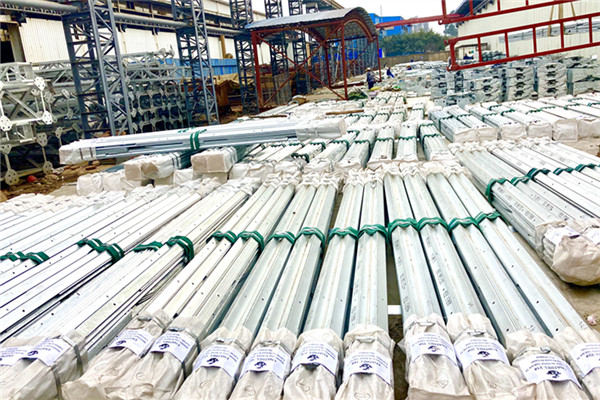

Package & Shipment